By Almighty

The actual work of takedown, replacement of

parts and reassembly.. takes only less than 20 minutes. I figure

the gun/or AEG unit would spend more time travelling if sent to

the dealer.

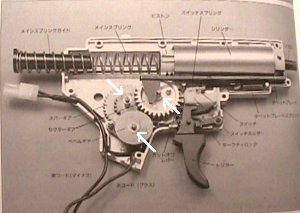

This is the inside of the AEG. The arrows point to where the bushings

are placed.

Here are the bushings, shown almost full size - these are the

metal replacements already.

Make sure the piston is in rest position by checking if feed nozzle

is forward. If not, fire gun several times until nozzle is forward.

To open AEG unit:

Lay AEG flat on table facing right. Remove all screws, and then

slowly pry top half off all around - keeping cylinder down with

your right index finger. This will keep the spring from buckling

and popping everything out.

Ease the (rear) spring guide out so as to relax

the spring, and then fully open the AEG.

To close AEG unit:

Compress the spring and put into its proper position, pressing

down on it and the cylinder to keep it from buckling. This is

best done with the right index or middle finger through the opening

of the upper half of the AEG housing.

Slowly close the AEG halves together and align

the gear arxles with their respective holes.

By Bad_Bob on Monday, July 13, 1998 -

08:55 pm:

Almighty beat me by a few minutes, but I might

as well post this anyway (nice pics, btw!)

I bought a non-working MP5, and since I couldn't do any harm,

I tore the whole thing apart, including the gearbox. It was really

quite straightforward; arrange the screws and parts in a logical

sequence so you put them back in the proper spots (some have different

threads and lengths).

When cracking open the gearbox, once the initial spray of parts

subsides (from the mainspring releasing; it's really not *that*

bad =), pull the halves apart. Three reduction gears are there,

and the last two seemed awfully "grind-prone" to me,

so I stuck an extra washer under one of them to reduce the "overlap"

a bit.

Don't forget to clean all the black crap off the trigger contacts

while you've got it open!

The two NON-obvious things when reassembling: make sure the plastic

nipple thingy (which slides back to let a BB in) is positioned

properly, and check the little ratcheting lever on the first reduction

gear; you wouldn't want that thing to be out of place or it'll

chew up the motor's sprocket.

Oh yeah, if you're curious: I did actually get the thing

working.

I wouldn't recommend it to just anybody, but if you've

assembled RC cars, this is a really simple do-it-yourself job.

MINI airsofts, on the other hand, are a can of worms; I may NEVER

get my mini-M16 put back together =(